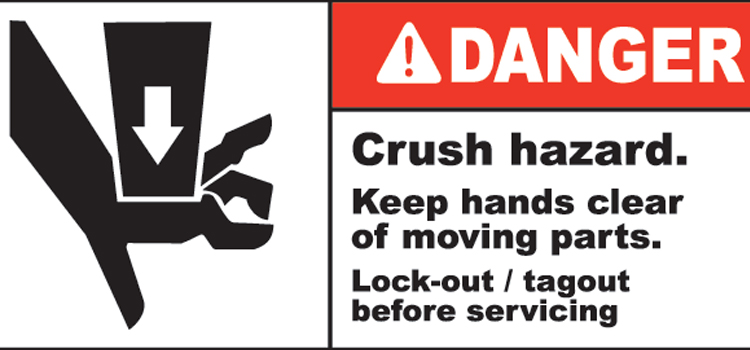

Crush points exist when two objects move toward each other, or when one object moves toward a stationary object.

Crushing Hazards

Types of machinery

- Reciprocating mechanisms, e.g. grain cleaners, box fillers, hop presses, baler needles

- Hydraulically raised equipment, e.g. trailers and rear doors, telescopic handler booms, combine headers

- Trailed machines with drawbars, e.g. trailers, balers, manure spreaders

- Linkage mounted machinery stability, e.g. post drivers, sprayers, fertiliser spreaders,Operator errors

- Reaching into or entering crush areas with the machine operating

- Incorrectly hitching tractors to implements and trailers

- Failing to support machinery during repairs or maintenance Design points

- Protect crush points so that workers cannot get their arms or hands trapped. This involves allowing adequate clearance around the moving parts.

- Prevent access to crushing points using fixed guards or interlocked

- Provide check valves and mechanical supports for hydraulic equipment that are easy to use from outside the danger area

- Ensure drawbar jacks and stands can support the machine in all conditions of use.

- Provide stabilisers for unbalanced machines when they are de-mounted.

- Removable devices should be stored on the machine in a safely accessible place when they are not needed.

safety diploma in kochi

Instructions for using this type of machinery must include clear guidance on:

- Controls

- Safe maintenance

- Relevant training

WhatsApp us

WhatsApp us